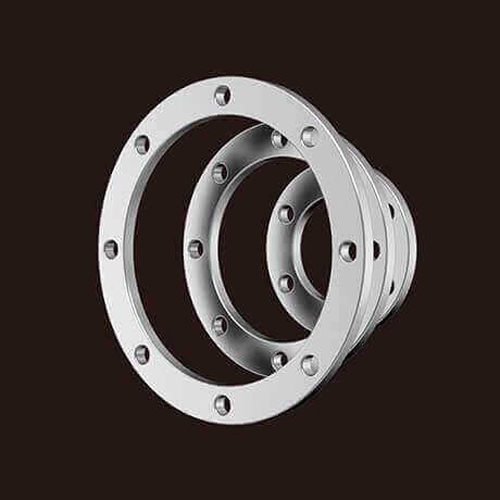

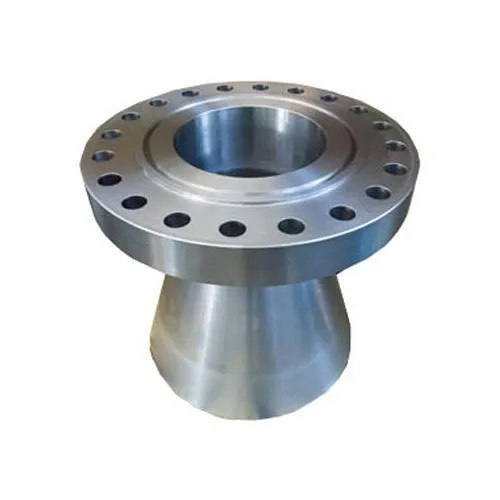

Centrifugal Casting

80 USD ($)/Number

Product Details:

- Usage & Applications Centrifugal Casting

- Product Type Cast Products

- Material Stainless Steel

- Surface Finishing Polished

- Weight Different Weight Available Kilograms (kg)

- Color Silver

- Click to View more

X

Centrifugal Casting Price And Quantity

- 100 Piece

- 80 USD ($)/Number

Centrifugal Casting Product Specifications

- Polished

- Cast Products

- Centrifugal Casting

- Silver

- Stainless Steel

- Different Weight Available Kilograms (kg)

Centrifugal Casting Trade Information

- CIF PORT

- 500 Piece Per Month

- 3 Week

- Sample costs shipping and taxes has to be paid by the buyer

- Wooden or as req

- All India

- ISO

Product Description

Steel Centrifugal Casting is a specialized manufacturing process for creating high-quality cylindrical or tubular steel components with exceptional precision and material properties. It involves melting the chosen steel alloy, preheating a cylindrical mold, and then pouring the molten metal into the rapidly rotating mold. The centrifugal force ensures even distribution, minimizing defects, and resulting in components with consistent wall thickness, fine-grained microstructure, and improved mechanical properties. Steel centrifugal casting is widely used in various industries, such as aerospace, automotive, and industrial applications, where reliability, precision, and material quality are critical. This method offers a cost-effective solution for producing durable and high-performance steel components.

FAQs of Centrifugal Casting:

Q: What material is used in the Centrifugal Casting product?

A: The Centrifugal Casting product is made from stainless steel.Q: What is the surface finishing of the Centrifugal Casting product?

A: The surface finishing of the Centrifugal Casting product is polished.Q: Is the Centrifugal Casting product available in different weights?

A: Yes, the Centrifugal Casting product is available in different weights measured in kilograms (kg).Q: What is the color of the Centrifugal Casting product?

A: The color of the Centrifugal Casting product is silver.Q: What are the usage and applications of the Centrifugal Casting product?

A: The Centrifugal Casting product is used specifically for centrifugal casting applications.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS