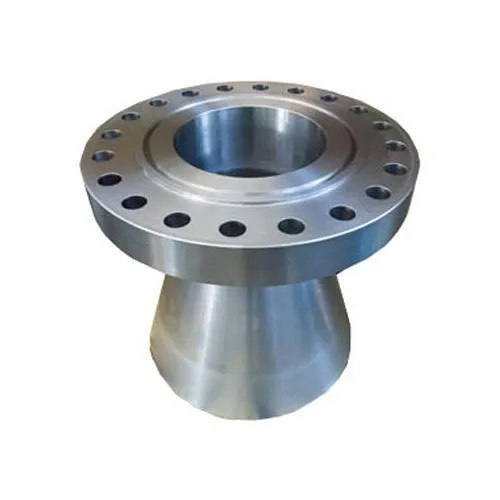

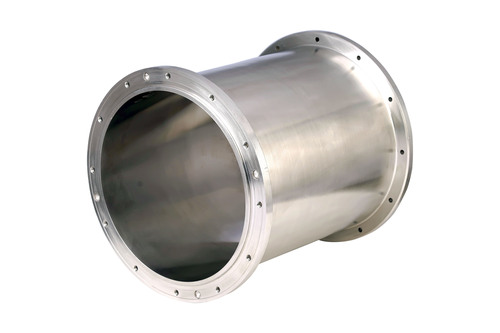

High Carbon High Chrome Centrifugal Casting

9000.00 INR/Number

Product Details:

- Usage & Applications Brus

- Product Type Cast Products

- Material Stainless Steel

- Surface Finishing Polished

- Weight Different Weight Available Kilograms (kg)

- Color Silver

- Click to View more

X

High Carbon High Chrome Centrifugal Casting Price And Quantity

- 9000.00 INR/Number

- 50 Piece

High Carbon High Chrome Centrifugal Casting Product Specifications

- Brus

- Different Weight Available Kilograms (kg)

- Cast Products

- Polished

- Silver

- Stainless Steel

High Carbon High Chrome Centrifugal Casting Trade Information

- Ex Works

- 150 Piece Per Month

- 4 Week

- Sample costs shipping and taxes has to be paid by the buyer

- Wooden

- All India

- ISO

Product Description

High Carbon High Chrome Centrifugal Casting is an advanced manufacturing process designed for producing cylindrical or tubular components from high-carbon, high-chrome steel alloys. This method involves melting the specialized alloy, preheating a cylindrical mold, and pouring the molten material into the rapidly rotating mold. The controlled centrifugal force ensures even distribution, minimizing defects and achieving superior material properties. HC-HC centrifugal castings offer exceptional hardness, wear resistance, and corrosion resistance, making them perfect for challenging applications such as mining, oil and gas, and heavy machinery. These components provide long-lasting, high-performance solutions for industries where durability and strength are critical.

FAQs of High Carbon High Chrome Centrifugal Casting:

Q: What is the surface finishing of the High Carbon High Chrome Centrifugal Casting?

A: The surface finishing of the High Carbon High Chrome Centrifugal Casting is polished.Q: What is the primary material used in the High Carbon High Chrome Centrifugal Casting?

A: The High Carbon High Chrome Centrifugal Casting is made of stainless steel.Q: What is the color of the High Carbon High Chrome Centrifugal Casting?

A: The color of the High Carbon High Chrome Centrifugal Casting is silver.Q: Are different weight options available for the High Carbon High Chrome Centrifugal Casting?

A: Yes, different weight options are available in kilograms (kg).Q: What are the usage and applications of the High Carbon High Chrome Centrifugal Casting?

A: The High Carbon High Chrome Centrifugal Casting is used for brus applications.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS